Context

- The Automotive Research Association of India (ARAI) is conducting a pilot project to explore isobutanol blending with diesel, following the limited success of ethanol–diesel blending.

- The project aims to:

- Develop cleaner-burning fuels for the transport sector.

- Reduce crude oil imports and enhance energy security.

- Utilize surplus ethanol feedstock effectively.

- Support India’s Net-Zero 2070 goals.

About Isobutanol

1. What it is

- Chemical formula: C4H10O

- Type: Four-carbon alcohol, clear, flammable liquid

- Energy content: Higher than ethanol, making it more efficient as a fuel

- Current uses: Solvent in paints, coatings, chemical synthesis, and emerging as a biofuel blendstock

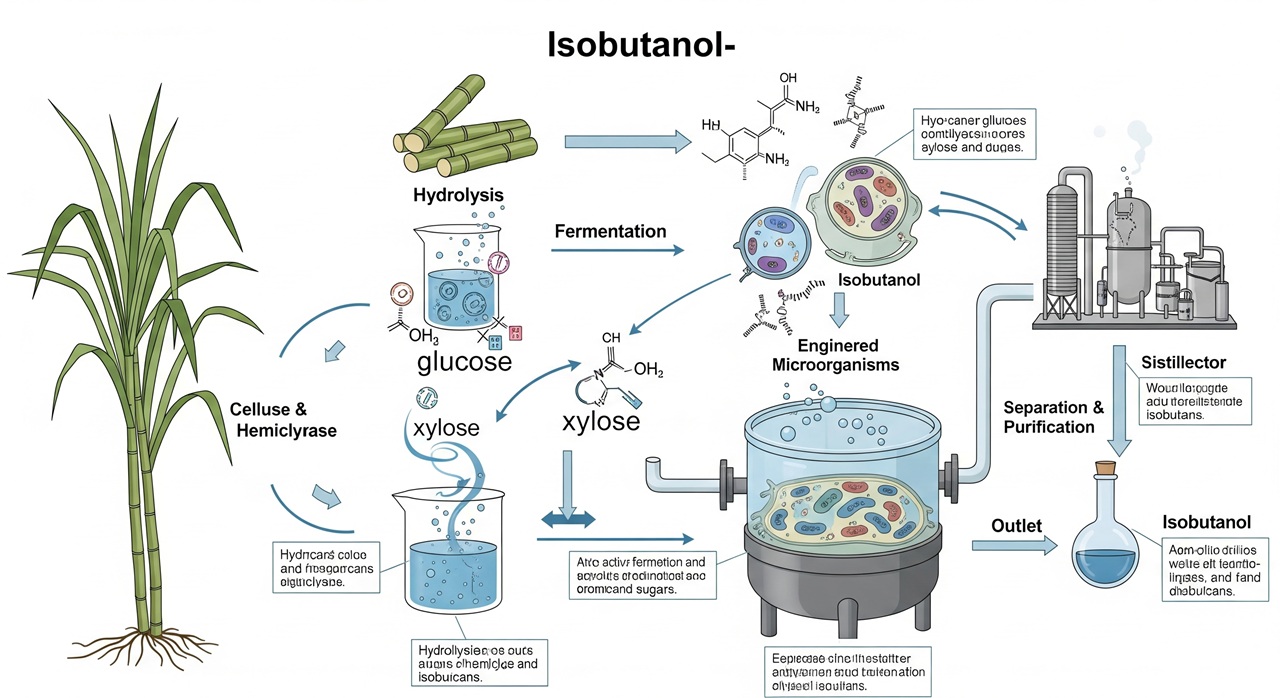

2. Formation Process

- Produced by fermenting natural sugars like cane juice, molasses, and grains using genetically engineered microbes.

- Requires sterile fermentation conditions.

- Sugar refineries need:

- Fermentation tank retrofitting

- Distillation units to separate ethanol and isobutanol

- Can be co-produced with ethanol using existing infrastructure with minor modifications

3. Aim of Blending

- Create a cleaner-burning diesel blend to reduce emissions.

- Reduce crude oil imports and enhance energy security.

- Provide a market for surplus ethanol, supporting the sugar sector’s sustainability.

- Contribute to India’s Net-Zero 2070 vision.

4. Key Features

- Higher Flash Point: Safer than ethanol, less volatile, reduces fire risk.

- Better Miscibility: Blends uniformly with diesel without extra additives.

- Energy-Dense: Higher calorific value than ethanol → improved fuel efficiency.

- Flexible Production: Co-produced with ethanol using minor refinery modifications.

- Emission Benefits: Potential to lower particulate emissions and reduce carbon intensity.

5. Applications

- Transport Sector: Up to 10% blend with diesel recommended.

- Solvent Industry: Paints, coatings, and chemical synthesis.

- Aviation & Marine Fuel: Research ongoing for sustainable fuel alternatives.

- Chemical Feedstock: Conversion into jet fuel, plastics, and rubber intermediates.

6. Limitations & Challenges

- Low Cetane Number: May reduce ignition quality → potential engine knocking.

- Engine Compatibility: Blends beyond 10% may impact performance and durability.

- Incremental Cost: Additives and blending infrastructure upgrades increase costs.

- Miscibility Issues: Full homogeneity may require biodiesel as a co-solvent.

Conclusion

- Isobutanol is a promising biofuel for diesel blending in India, offering:

- Safer handling, better miscibility, and higher energy density compared to ethanol.

- Challenges like engine compatibility, costs, and miscibility need to be addressed.

- Successful implementation can:

- Reduce fossil fuel dependence

- Strengthen the sugar–ethanol ecosystem

- Contribute significantly to Net-Zero 2070 targets

Source : The Hindu